Product Description

In many plants, film cutting isn’t “just cutting.” It’s the moment where tiny length drift becomes lamination misalignment, where static turns clean sheets into a clingy mess, and where a rough edge becomes a downstream jam. This machine is built to make that moment calm and predictable.

From the first pull of the roll to the final sheet, the process feels controlled: the film feeds smoothly, the drive responds quickly, and the cut lands with a crisp, repeatable finish. Instead of fighting curl, uneven tension, or inconsistent lengths, operators can focus on output and quality. When your production schedule changes mid-shift—different widths, different lengths, different substrates—the setup is designed to be fast, measurable, and stable. The goal is simple: deliver sheets that look and behave the way your next process expects, every time.

Product Features and Highlights

This model focuses on production-grade consistency, not gimmicks. You’ll notice it in the parts you touch every day: stable feeding, reliable control logic, and a cutting behavior that stays steady as the roll diameter decreases.

Key advantages for B2B users:

High precision cutting: Cutting precision is 0.03mm, supporting applications where sheet-to-sheet consistency matters

High efficiency output: Cutting speed up to 100 cut/min, suitable for continuous production

High automation level: Cutting, feeding, and collecting are designed to run with minimal manual intervention

Servo + PLC combination: A practical control structure that supports repeatable motion and stable cycles

Flexible cutting modes: Complete cut is standard; kiss-cut is optional for special processes

Material flexibility: Supports a wide range of roll materials beyond PET film

Operator-friendly options: Eye mark device (optional), plus static eliminator and conveyor belt options for real-world handling needs

Automatic unwinding: Helps maintain steady feeding during long runs

Air shaft loading: A proven approach for quicker roll mounting and safer handling

Material Compatibility and Applications

Polyester film behaves differently depending on thickness, coating, and storage conditions. Some rolls unwind like silk; others fight back with curl memory and static. This machine is built to stay stable across those variations, especially when paired with practical options like static control and conveyor transfer.

Common application scenarios:

Electrical and insulation films: PET/Mylar insulation sheets for electrical products and general industrial insulation tasks

Electronics and flexible circuits: PCB, FPC, and protective films where consistent length and neat edges reduce defects

Battery and energy materials: Lithium battery film and related flexible materials where cutting quality affects downstream yield

Foil and composite materials: Aluminum foil, copper foil, and laminate structures where clean edges protect handling and stacking

Packaging and converting lines: Roll-to-sheet work where stable lengths simplify counting, packing, and kit assembly

Supported material thickness range is 0.5mm–20mm (depending on different materials), helping you cover both thin films and thicker sheet-like substrates in one equipment family.

Precision, Cut Quality, and Waste Control

The easiest way to lose money in cutting is through small, repeated errors: a length that creeps by fractions, edges that fray and create dust, or sheets that stack poorly and require rework. This machine is designed to reduce those “quiet losses.”

What contributes to cleaner output:

Stable length control with PLC + servo coordination, improving repeatability across long runs

Consistent cut timing designed to hold performance even as the roll diameter changes

Optional eye mark device for workflows where print marks or registration cues matter

Reduced waste from miscuts by improving repeatability and minimizing the need to “trim extra” as insurance

Better sheet handling with optional conveyor belt to move sheets cleanly and reduce scuffs, corner damage, and stack disorder

If your team tracks scrap causes, you’ll typically see the biggest improvements in “length out of spec,” “stacking issues,” and “handling damage”—the categories that eat time because they are small but frequent.

Automation and Operator Experience

A cutting machine shouldn’t depend on one “expert operator” to run well. In a B2B environment, you want consistent output across shifts, across operators, and across different product mixes. This machine is designed with that reality in mind.

Operator-facing benefits:

Less manual intervention: Automated cutting, feeding, and collecting reduce repetitive tasks

Clearer process stability: Servo-driven motion helps the machine “feel” consistent—less surging, fewer surprises

Easier changeover: Multiple max-width options across the LT series let you match capacity to job requirements

Safer roll handling: Air shaft loading supports more controlled mounting and removal

Process add-ons: Static eliminator option addresses a frequent film-cutting pain point—sheets sticking, drifting, or attracting dust

Production continuity: Automatic unwinding supports longer runs with steadier feeding behavior

In day-to-day use, the biggest improvement often shows up as reduced “micro-stops”—those brief interruptions that don’t look serious, but destroy your real hourly output.

Configuration Options and Line Fit

No two factories run the same. Some prioritize maximum speed, others prioritize defect control, and many must balance both while working with limited space. This product family provides multiple width configurations, plus options to match your material and handling needs.

Configuration flexibility includes:

Max cutting width options: 360, 500, 600, 700, 1000mm

Cutting length range: up to 0–9999.99mm, supporting short-sheet jobs and long-format requirements

Cut type: Complete cut standard; kiss-cut optional for special processing needs

Eye mark device: Optional for registration-based cutting

Static eliminator: Optional for improved film handling and cleaner stacking

Conveyor belt: Optional to improve sheet transfer and protect surface quality

This approach helps procurement teams avoid “over-buying” capacity while still leaving room for future product expansion.

Production Workflow and Integration

A roll-to-sheet cutter becomes more valuable when it fits cleanly into your upstream and downstream steps. This machine is designed to support a straightforward production flow that reduces handling and improves predictability.

Typical workflow:

Roll loading on air shaft

Automatic unwinding and controlled feeding

Servo/PLC-controlled cutting cycle

Sheet transfer (with optional conveyor belt)

Counting, stacking, and packaging

Integration-friendly outcomes:

More predictable sheet lengths simplify downstream lamination, punching, printing, or assembly

Cleaner stacks reduce packaging labor and rework

Lower scrap variance helps planning teams forecast material consumption more accurately

Higher effective uptime improves OEE without needing extreme speed settings

For many plants, the real ROI is not just speed—it’s reducing the hidden cost of re-cutting, re-stacking, and chasing dimensional drift.

Why Choose An Automatic Polyester Film Cutting Machine?

1. High efficiency: The roll to sheet cutting machine can cut paper quickly and accurately, improving production efficiency.

2. High precision: The reel to sheet cutting machine has a high-precision cutting function, which can achieve precise cutting of paper of various specifications.

3. High degree of automation: The reel to sheet cutting machine can automatically complete the process of cutting, feeding, and collecting without manual intervention, which greatly improves the work efficiency and safety.

4. Wide applicability: The reel to sheet cutting machine is suitable for various types of paper, including soft, hard, double-sided coating, etc.

5. Resource saving: The cutting accuracy of reel to sheet cutting machine is high, which can effectively avoid the waste of paper due to inaccurate cutting, thereby saving resources.

6. Good environmental protection: The reel to sheet cutting machine adopts advanced technology and equipment, which can achieve low energy consumption and low pollution production mode, and meet the requirements of environmental protection.

Features of Polyester Film Cutting Machine

1. The max cutting width option: 360, 500, 600, 700, 1000mm.

2. Cutting Precision: 0.03mm

3. Material thickness: 0.5mm-20mm (according to different materials)

4. Cutting speed: 100cut/min;

5. Both kiss-cut and complete cut are available; Complete cut is for standard machine, and kiss-cut is an option;

6. A conbination of PLC and servo motor.

7. Eye mark device for optional

8. An air shaft as the loading shaft;

9. Two accessories, static eliminator and conveyor belt, for you to choose

10. Automatic unwinding function;

Machine Parameters

| Item Number | LT-360 | LT-500 | LT-600 | LT-700 | LT-1000 |

| Web Width | 0-360mm | 0-500mm | 0-600mm | 0-700mm | 0-1000mm |

| Cutting length | 0-9999.99mm | 0-9999.99mm | 0-9999.99mm | 0-9999.99mm | 0-9999.99mm |

| Cutting speed | 100 cut/min | 100 cut/min | 100 cut/min | 100 cut/min | 100 cut/min |

| Cutting precision | 0.03mm | 0.03mm | 0.03mm | 0.03mm | 0.03mm |

| Voltage | 220V/380V | 220V/380V | 220V/380V | 220V/380V | 220V/380V |

| Size | 1100x1420x1280mm | 1250x1420x1280mm | 1350x1420x1280mm | 1450x1420x1280mm | 1730*1420x1280mm |

| Weight | 320kg | 380kg | 400kg | 420kg | 450kg |

| Total Power | 2.2kw | 2.2kw | 2.2kw | 2.2kw | 2.2kw |

Machine photos

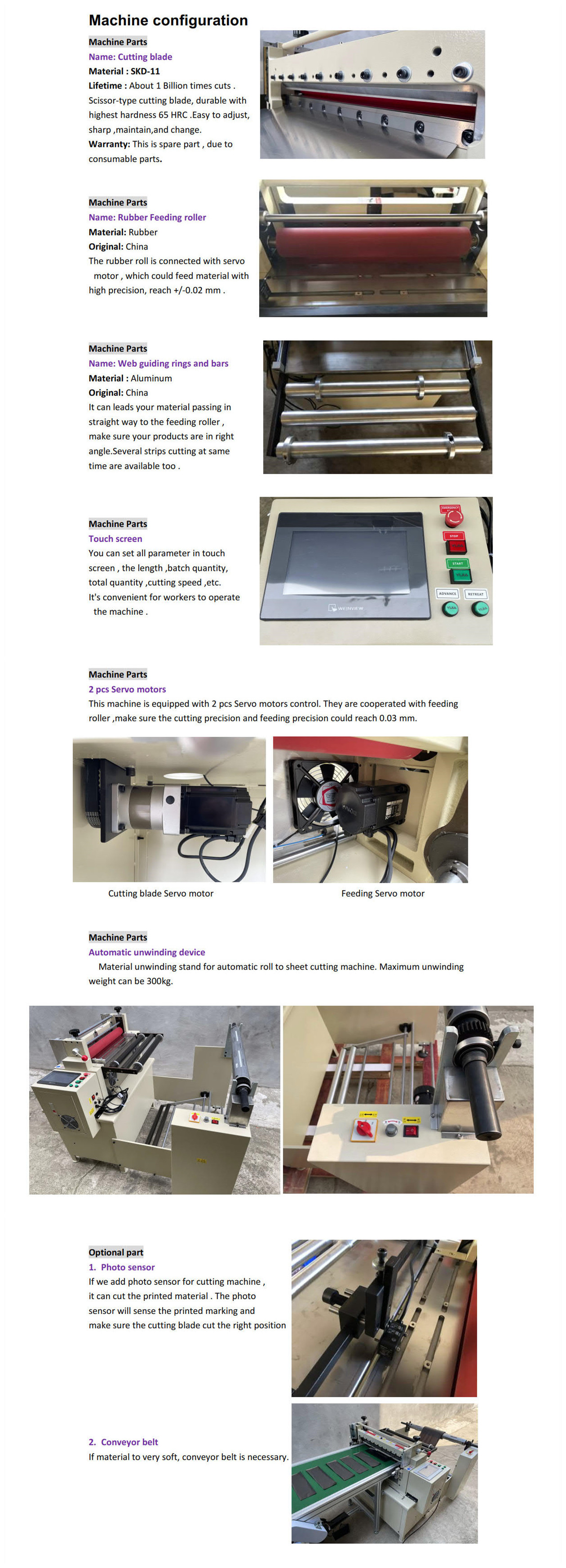

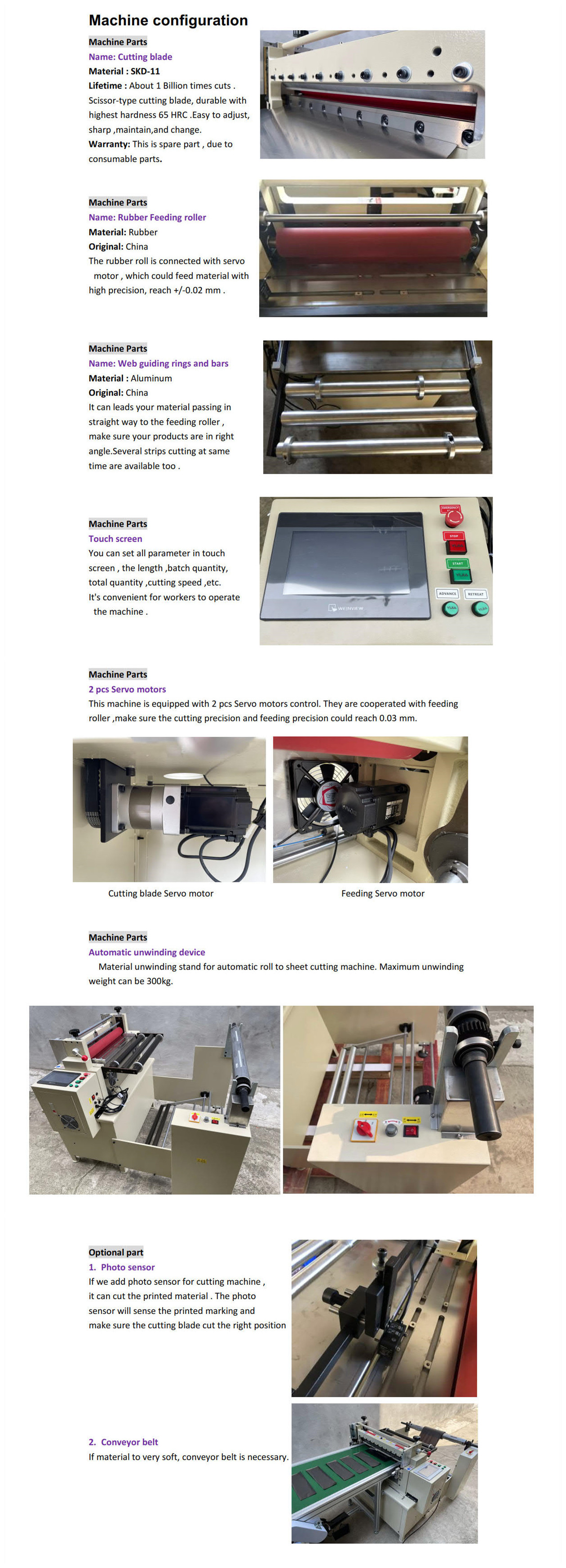

Machine configuration

CE certificate

Comments from our clients