Automatic shrink sleeve roll to sheet cutting machine

Product Description

Many customers come to roll-to-sheet cutting after a familiar moment: orders are growing, the film is getting thinner or more technical, and manual or semi-manual cutting becomes the bottleneck. Operators start compensating by “feel” — adjusting tension by instinct, trimming edges, re-cutting short sheets, and stacking by hand to keep piles from sliding. It works… until it doesn’t.

This machine was developed for that reality. It is intended to be the quiet, reliable step in your line — the one that turns a large roll into sheet output that looks disciplined and professional. When it runs well, you’ll notice it in small sensory details: the web tracks smoothly, the cutting action stays clean, and the collected sheets sit flatter and more aligned. Instead of chasing the process, your team can run it with standard settings, documented checks, and repeatable results.

The result is not just “automation.” It’s a cleaner handoff to the next station — printing, labeling, die-cutting, sleeve forming, or packing — where stability matters most.

Product Features and Highlights

Core capabilities that directly support production outcomes:

Multiple cutting width options so you can match your web width without overbuying capacity

High cutting precision designed for demanding materials and tight tolerance expectations

PLC and servo motor combination for stable motion control and repeatable cycles

Complete cut as standard, with kiss-cut available as an option for specific workflows

Optional eye mark device to support applications that require registration alignment

Air shaft loading designed for faster roll changes and secure web mounting

Optional static eliminator to reduce clinging, dust attraction, and handling issues on film webs

Optional conveyor belt to improve collection flow and reduce manual handling

Automatic unwinding function to support continuous, stable feeding

Materials and Applications

This machine is designed for converters who work with mixed materials and want one cutting platform that can handle both metal and non-metal webs. It is suitable for roll-to-sheet cutting of:

Shrink sleeve and label film webs used in packaging workflows

PET, PC, PVC films and other plastic webs

Aluminum foil and copper foil for industrial converting

Lithium battery film and related specialty materials

PCB, FPC related sheet cutting needs

Flannelette and certain non-metal flexible materials

Metal foil and other web materials where clean sheet edges and dimensional control matter

Typical B2B use cases:

Sleeve-label production: cutting film into consistent sheets for downstream converting steps

Industrial film converting: preparing sheet sizes for lamination, testing, or forming

Foil processing: sheet preparation for packaging, battery, or specialty industrial use

Multi-SKU workshops: one line that can switch between materials based on planned runs

Practical note for buyers: the “best” setup depends heavily on your material behavior — stiffness, static tendency, surface friction, and thickness. Sharing your real sample specs during RFQ helps lock in the most stable configuration.

Performance Specifications and Production Planning

In B2B production, performance numbers are only useful when they translate into scheduling confidence. This machine is defined around a simple promise: accurate sheets at a consistent operating rhythm.

Key performance points:

Cutting speed: 100 cut/min

Cutting precision: 0.03 mm

Cutting length range: 0–9999.99 mm

Material thickness: 0.5–20 mm, depending on different materials

How to use these specs in planning:

Use cutting length and speed to estimate cycles per shift, then subtract realistic roll-change and inspection time.

Use the precision reference to set QC checkpoints: first-off approval, mid-run sampling, and post-changeover verification.

If you run thin films prone to static or curl, plan for optional anti-static and smoother collection flow to protect usable output at higher speeds.

Quick planning table:

| What you want | What to focus on | Why it matters |

| Higher daily output | Stable feeding + consistent collection | Throughput collapses when stacks become messy |

| Lower scrap | Precision + correct cutting mode | Errors often come from the last 5% of control |

| Easier changeover | Air shaft + standard settings | Saves time and reduces operator variability |

| Better handling of film | Static control + conveyor option | Cleaner piles, fewer sheets sticking together |

Cutting Modes and Quality Control

Different products require different “cut feelings.” Some applications want a decisive full separation; others want controlled scoring that stays intact for later processing.

Complete cut is standard and is ideal for sheet output that will be stacked, counted, packed, or fed into the next station as individual sheets.

Kiss-cut is available as an option when your process requires partial cutting or controlled separation (for example, workflows that need the material to remain supported before the next step).

For QC teams, recommended checks include:

First-off inspection at target length and width, confirming clean edges and consistent dimensions

Periodic sampling during the run, especially after roll changes

Visual checks for edge burrs, stretching, or deformation on heat-sensitive films

Collection checks: the stack is often the earliest warning signal of tension or static problems

Control System and Operator Experience

A machine that “looks automated” but still depends on operator instincts will not scale across shifts. This system uses a PLC and servo motor combination to support repeatable motion and standardized operation.

What that means on the floor:

Settings can be run as documented recipes rather than “operator memory”

Servo-driven motion helps stabilize cycle timing and cut repeatability

Operators can focus on feeding discipline, inspection, and collection — not constant micro-adjustment

For B2B plants, this improves:

Training time for new operators

Consistency between day and night shifts

Traceability of settings when customer complaints require investigation

Web Handling and Unwinding Stability

A roll-to-sheet cutter lives or dies by web behavior. Even small variations in feeding can become visible as skewed sheets, uneven lengths, or stacks that lean.

This machine includes:

Automatic unwinding function to support stable feeding during continuous operation

Air shaft loading, helping secure the roll and reduce setup time

Recommended operating discipline for better stability:

Confirm roll alignment and loading tightness before start

Maintain clean rollers and a dust-controlled environment for film webs

For static-prone materials, consider adding the optional static eliminator to reduce cling and handling issues

Use the optional conveyor belt when your sheets need smoother transfer and cleaner collection without manual pulling

Registration and Eye Mark Option

Some sleeve and printed film applications require alignment to print marks or repeat lengths. For those cases, an eye mark device is available as an option.

How this helps in production:

Better alignment consistency when your downstream step depends on printed position

Reduced “adjust-and-reject” cycles at the start of a run

More predictable cut placement when material repeat and visual features matter

If you do not require registration, many customers choose to keep the base configuration simpler and invest instead in collection stability and static control. The right choice depends on how strict your downstream alignment requirements are.

Customization and Configuration Options

B2B buyers rarely want a single fixed machine — they want the right configuration for their web, their space, and their output style.

Available configuration directions include:

Width selection by model to match your web width and growth plan

Optional eye mark device for registered cutting needs

Optional static eliminator for film webs where dust attraction and sticking create scrap

Optional conveyor belt to improve sheet transfer and keep stacks neater

Kiss-cut option for workflows that require controlled cutting rather than full separation

A practical way to decide options:

If your scrap is mostly “dimensional,” focus on setup and control discipline.

If your scrap is mostly “handling,” invest in static reduction and better collection flow.

If your scrap is mostly “alignment,” consider the eye mark option and tighter process validation.

Quality, Compliance, and Documentation

For procurement and engineering teams, acceptance is not only about performance; it’s also about documentation and compliance readiness.

This machine is presented with:

CE certificate shown as available

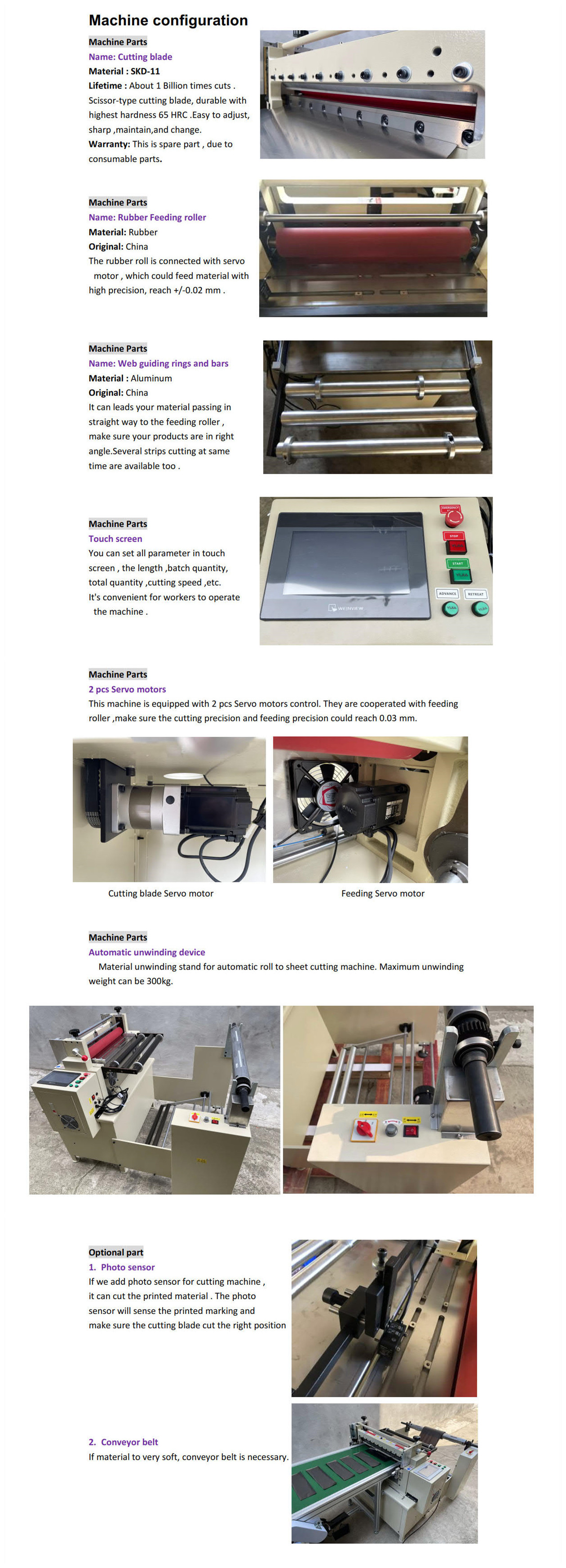

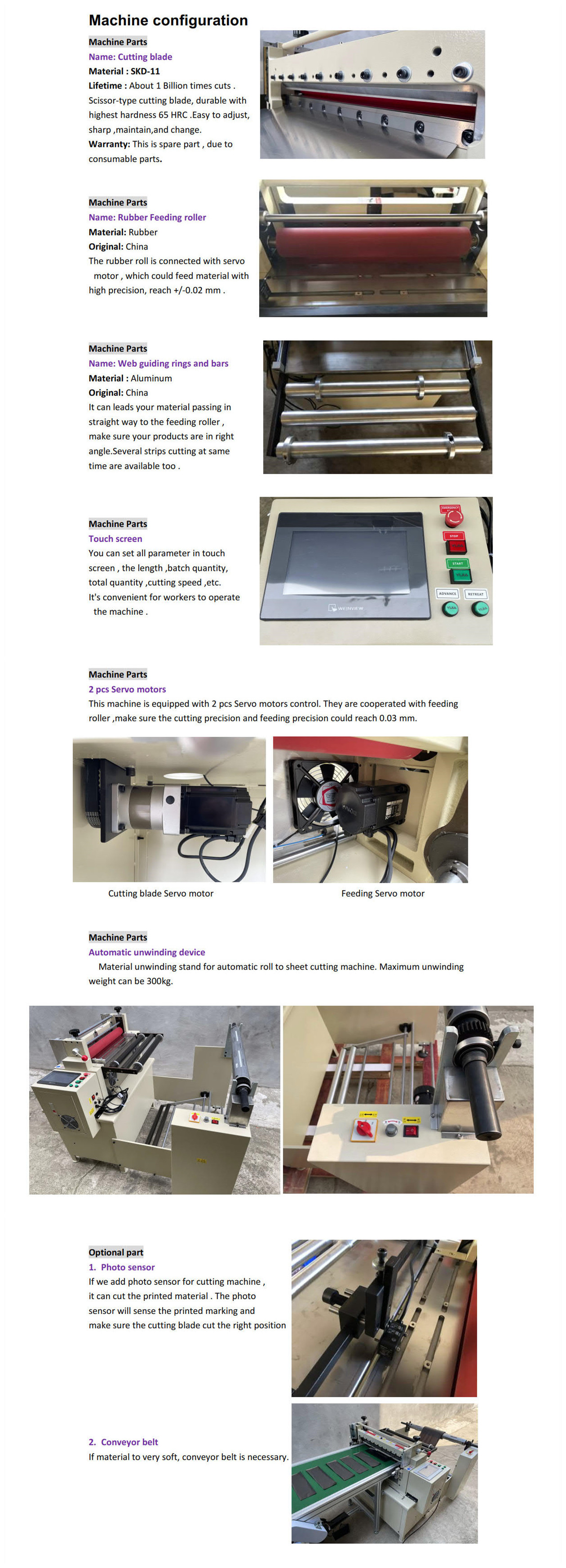

Machine configuration reference materials

Practical support for factory acceptance testing: length checks, output consistency checks, and option verification

If you run regulated supply chains or export-focused production, define in advance:

Your required test documents and inspection format

Packaging standards for shipment

Spare parts expectations for the first year of operation

Installation, Service, and Long-Term Running

The most expensive machine is the one that runs inconsistently. Good service is not a promise — it’s a plan.

Recommended support approach for B2B projects:

Pre-installation checklist: power, footprint, material handling path, operator safety zone

Commissioning guidance: first-off validation, stable run settings, option verification

Operator training: roll loading discipline, changeover steps, basic troubleshooting

Maintenance basics: cleaning routines, inspection schedule, and consumable planning

When you provide clear information at RFQ stage, the commissioning period becomes shorter, and your ramp-up is smoother.

Why Choose An Automatic Roll to Sheet Cutting Machine?

1. High efficiency: The roll to sheet cutting machine can cut paper quickly and accurately, improving production efficiency.

2. High precision: The reel to sheet cutting machine has a high-precision cutting function, which can achieve precise cutting of paper of various specifications.

3. High degree of automation: The reel to sheet cutting machine can automatically complete the process ofcutting, feeding, and collecting without manual intervention, which greatly improves the work efficiency and safety.

4. Wide applicability: The reel to sheet cutting machine is suitable for various types of paper, including soft, hard, double-sided coating, etc.

5. Resource saving: The cutting accuracy of reel to sheet cutting machine is high, which can effectively avoid the waste of paper due to inaccurate cutting, thereby saving resources.

6. Good environmental protection: The reel to sheet cutting machine adopts advanced technology and equipment, which can achieve low energy consumption and low pollution production mode, and meet the requirements of environmental protection.

Features of shrink sleeve roll to sheet cutting machine

1. The max cutting width option: 360, 500, 600, 700, 1000mm.

2. Cutting Precision: 0.03mm

3. Material thickness: 0.5mm-20mm (according to different materials)

4. Cutting speed: 100cut/min;

5. Both kiss-cut and complete cut are available; Complete cut is for standard machine, and kiss-cut is an option;

6. A conbination of PLC and servo motor.

7. Eye mark device for optional

8. An air shaft as the loading shaft;

9. Two accessories, static eliminator and conveyor belt, for you to choose

10. Automatic unwinding function;

Machine Parameters

| Item Number | LT-360 | LT-500 | LT-600 | LT-700 | LT-1000 |

| Web Width | 0-360mm | 0-500mm | 0-600mm | 0-700mm | 0-1000mm |

| Cutting length | 0-9999.99mm | 0-9999.99mm | 0-9999.99mm | 0-9999.99mm | 0-9999.99mm |

| Cutting speed | 100 cut/min | 100 cut/min | 100 cut/min | 100 cut/min | 100 cut/min |

| Cutting precision | 0.03mm | 0.03mm | 0.03mm | 0.03mm | 0.03mm |

| Voltage | 220V/380V | 220V/380V | 220V/380V | 220V/380V | 220V/380V |

| Size | 1100x1420x1280mm | 1250x1420x1280mm | 1350x1420x1280mm | 1450x1420x1280mm | 1730*1420x1280mm |

| Weight | 320kg | 380kg | 400kg | 420kg | 450kg |

| Total Power | 2.2kw | 2.2kw | 2.2kw | 2.2kw | 2.2kw |

Machine photos

Machine configuration

CE certificate

Comments from our clients