Product Description

On a busy converting floor, an “automatic paper cutting machine” is judged by small, practical details: the clean snap of a cut that doesn’t fray the edge, the steady pull of a web that doesn’t wander, and the satisfying thump of finished sheets landing in a consistent rhythm. The LT Series is built for that kind of daily production reality. It is designed to take material from rolls to sheets with high precision, helping B2B teams reduce trimming, re-stacking, and rework that quietly eats into margin.

Many factories start with a simple goal: ship sheets that match the customer’s spec every time. Then the complications arrive—mixed materials, different thicknesses, frequent changeovers, and operators who must keep output stable through an entire shift. The LT Series addresses those friction points with servo-driven feeding, PLC control, and options that fit real workflows such as eye mark tracking and a conveyor belt for smoother delivery. The machine is suited for paper, aluminum foil, copper foil, PET, PC, PVC, PCB, FPC, lithium battery film, flannelette, metal foils, and other non-metal roll materials. When you hear the line running smoothly—no jerky pulls, no sudden stops—your team feels the difference: fewer interruptions, calmer operation, and output that is easier to pack and sell.

Product Features and Highlights

Precision that protects yield: Cutting precision is specified at 0.03 mm, supporting tighter tolerances and reducing “almost-right” sheets that become scrap at inspection or finishing.

Flexible width choices for different product lines: Max cutting width options include 360, 500, 600, 700, and 1000 mm, letting you match the machine to your roll supply and finished sheet formats.

Handles real-world thickness variation: Material thickness range is 0.5–20 mm depending on different materials, making the LT Series useful beyond standard paper-only operations.

One platform, two cutting styles: Full cut is standard for clean separation; kiss-cut is optional for workflows where you want to cut the top layer without cutting the liner.

Automation that reduces operator fatigue: Automatic unwinding and servo-driven control reduce constant manual corrections and help keep output stable during long runs.

Production-ready options: Eye mark device for registration-sensitive jobs, plus optional static eliminator and conveyor belt to improve handling and downstream efficiency.

Stable loading: Air shaft as the loading shaft supports consistent web holding and quicker roll changes.

Applications and Material Compatibility

If your business ships cut sheets, the pressure is always the same: customers want consistent dimensions, neat edges, and repeatable batches. The LT Series is positioned for B2B environments where roll material must be converted into sellable sheets efficiently, whether you operate in printing support, packaging components, industrial film converting, or technical material preparation.

Material compatibility matters because it directly affects your ability to accept diverse orders. This machine is described for paper as well as aluminum foil, copper foil, PET, PC, PVC, PCB and FPC-related materials, lithium battery film, flannelette, metal foils, and other non-metal materials from rolls. That breadth is useful when your product portfolio includes both “soft” and “stiff” webs, or when you must switch between clean-cut paper jobs and more technical flexible substrates. In practical terms, operators notice compatibility through touch and handling: some webs feel dry and crisp, others feel slick and springy, and some carry static that makes sheets cling. Options like a static eliminator and conveyor belt exist for those everyday realities, helping sheets separate cleanly, travel smoothly, and stack more predictably for packing or downstream processing.

Cutting Technology and Process Options

The value of an automatic roll-to-sheet cutter is not just that it cuts—it cuts in a way that keeps the web stable. The LT Series is built around a PLC and servo motor combination, which supports controlled feeding and repeatable cut lengths across re-orders. This is especially important when your customers expect batches to match earlier deliveries and when your internal QC checks rely on consistent dimensions.

Two cutting approaches are supported to match different products:

Full cut: Standard configuration for clean separation into individual sheets, ideal for straightforward roll-to-sheet conversion.

Kiss-cut: Optional configuration for jobs like label and liner-style products where the top layer must be cut without damaging the backing.

Registration-sensitive jobs can benefit from an eye mark device option, which is relevant when you must align cuts with printed marks or repeating graphics. When set correctly, the machine’s rhythm becomes consistent: a smooth feed, a precise cut, and a repeatable cadence that reduces the “operator guessing” that often causes waste. For B2B teams, that stability is not a luxury—it is what makes lead times predictable and customer complaints rare.

Automation and Control System

B2B production lines succeed when output is repeatable across shifts and operators. The LT Series uses a PLC and servo motor combination to support consistent feeding and cutting. This matters because many production problems are not “big failures,” but small variations that accumulate: slightly drifting lengths, inconsistent stops, or operator-dependent adjustments that create variability between batches.

Automation features include automatic unwinding, reducing the need for constant manual intervention. For operators, good automation feels calm: fewer sudden pulls, fewer corrections, and a smoother rhythm that reduces fatigue. For managers, it looks like improved scheduling confidence and fewer quality holds. Optional features like an eye mark device can add another layer of control for printed or patterned materials, helping the machine respond to real-world variability in the web rather than forcing operators to “make it work” through manual tweaks.

Safety, Compliance, and Shop-Floor Practicality

Safety and predictability are part of product quality in B2B environments. A cutting line that is stable and controlled is also a safer line: fewer jams, fewer rushed interventions, and fewer moments where operators feel pressured to “fix it quickly.” While specific safety hardware varies by configuration, the practical safety goal is consistent across modern automatic cutters: controlled motion, clear operator interaction, and a workflow that avoids unnecessary manual contact with moving parts.

Compliance readiness also supports procurement decisions, especially for buyers who must pass internal audits. The product page indicates a CE certificate section, which is relevant for customers who require documented conformity for import, installation, or internal compliance checks. For global buyers, clear documentation and predictable machine behavior often matter as much as speed—because they reduce commissioning risk and shorten the time from delivery to stable production.

Reliability, Maintenance, and Consumables

Reliable production is the outcome of two things: stable design and practical maintenance habits. The LT Series emphasizes precision and automation, which helps reduce stress on the process by avoiding unstable feeds and repeated manual corrections. Over time, fewer disruptions often translate into lower wear caused by jams and emergency stops.

A maintenance plan for roll-to-sheet cutters typically focuses on:

Cutting components: Keep blades and cutting interfaces clean and monitored to preserve edge quality and consistent cut behavior.

Web handling points: Inspect and clean contact areas that influence tracking and feeding stability.

Drive and control checks: Verify servo and PLC-related settings during product changeovers to keep repeatability strong.

Static and delivery: If you run films or foils that cling, optional static elimination can reduce the “dusty cling” sensation and the nuisance of sheets sticking together, improving packing efficiency.

For B2B operators, good maintenance is not complicated—it is disciplined. When the machine runs with a steady sound and predictable cadence, you can trust your output, protect your shift targets, and reduce the stress that comes with late-order pressure.

Customization and Options

Different factories mean different priorities: some buyers need registration accuracy, some need better handling, and some need width flexibility to support changing product lines. The LT Series supports practical customization through model selection and optional features.

Common configuration decisions:

Width selection: 360 / 500 / 600 / 700 / 1000 mm maximum cutting width options

Cutting mode: Full cut standard, kiss-cut optional

Registration option: Eye mark device

Handling upgrades: Static eliminator and conveyor belt options

Loading method: Air shaft as the loading shaft

Power specification: 220V/380V options listed in the parameters table

These choices help align the machine to your production reality instead of forcing your production reality to adapt to a one-size setup. For procurement teams, this also improves total cost of ownership: you invest in features that remove bottlenecks rather than paying later through scrap, overtime, or repeated manual handling.

Machine Parameters

| Item Number | LT-360 | LT-500 | LT-600 | LT-700 | LT-1000 |

| Web Width | 0-360mm | 0-500mm | 0-600mm | 0-700mm | 0-1000mm |

| Cutting length | 0-9999.99mm | 0-9999.99mm | 0-9999.99mm | 0-9999.99mm | 0-9999.99mm |

| Cutting speed | 100 cut/min | 100 cut/min | 100 cut/min | 100 cut/min | 100 cut/min |

| Cutting precision | 0.03mm | 0.03mm | 0.03mm | 0.03mm | 0.03mm |

| Voltage | 220V/380V | 220V/380V | 220V/380V | 220V/380V | 220V/380V |

| Size | 1100x1420x1280mm | 1250x1420x1280mm | 1350x1420x1280mm | 1450x1420x1280mm | 1730*1420x1280mm |

| Weight | 320kg | 380kg | 400kg | 420kg | 450kg |

| Total Power | 2.2kw | 2.2kw | 2.2kw | 2.2kw | 2.2kw |

Machine photos

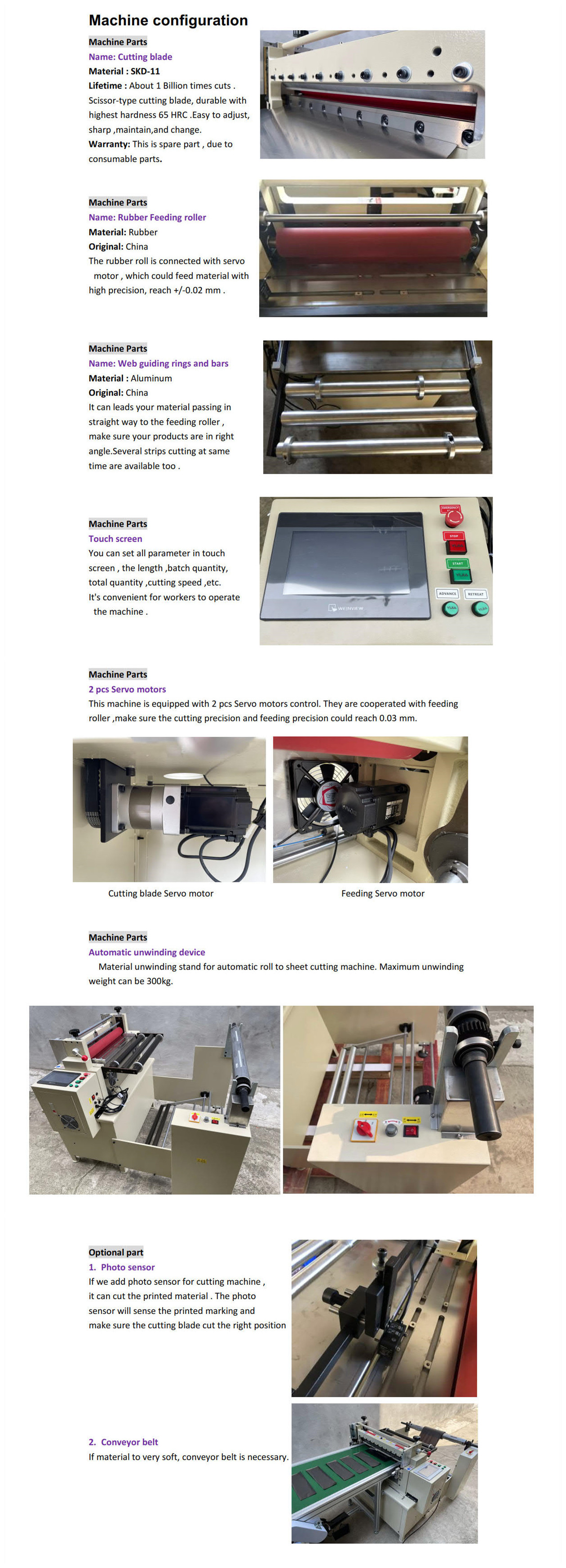

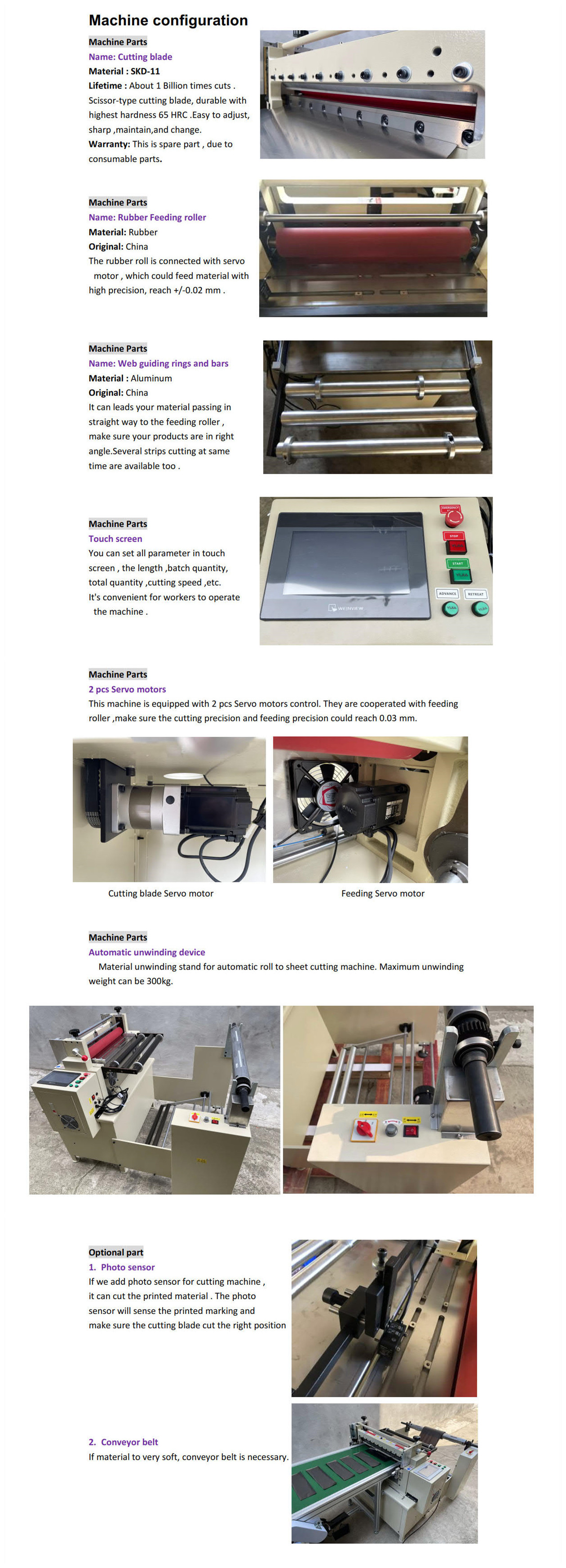

Machine configuration

CE certificate

FAQ

What is this machine best suited for, paper only or multiple roll materials

This machine is described for roll-to-sheet cutting of paper and also aluminum foil, copper foil, PET, PC, PVC, PCB, FPC, lithium battery film, flannelette, metal foils, and other non-metal roll materials. If you run mixed materials, model selection and option selection matter because different webs behave differently in feeding, static build-up, and stacking.

How do I choose between LT-360, LT-500, LT-600, LT-700, and LT-1000

Start with your maximum incoming roll width and your future product plan. If you buy rolls up to 500 mm now but plan to add wider SKUs later, choosing a wider model can protect your investment. Then confirm the space available on your floor and your preferred handling workflow, because larger width models also influence layout and material movement.

What is the difference between full cut and kiss-cut

Full cut separates the material into individual sheets and is standard. Kiss-cut is optional and is used when you need to cut only the top layer while keeping the backing intact, which is common for liner-based products. Your decision should be driven by your product portfolio, not by a generic “more features is better” approach.

What should I prepare for installation in terms of power and operation

The parameters list voltage options of 220V/380V depending on configuration. In addition to power, prepare a clean, organized roll handling area so the web feeds smoothly, and define basic operating rules for changeover, inspection, and cleaning. Stable upstream handling often has as much impact on output quality as the cutter itself.

How can I reduce sticking or handling issues when cutting films or foils

Films and foils can build static and cling, making sheets stick together or behave unpredictably during collection. Consider the optional static eliminator and conveyor belt if your workflow requires clean separation, smooth delivery, and easier packing. These options are practical improvements that save labor time and reduce the frustration of re-stacking and re-counting.