Product Description

Every roll-converting work

shop has the same pressure point: the moment a customer opens a carton and runs a fingertip along the edge. If the roll telescopes, if the slit line wavers, or if the winding is too loose and “breathes” during transport, the customer doesn’t remember your on-time delivery. They remember the rework. The Automatic paper roll slitting machine is built to protect your reputation at that exact moment. It’s a compact, production-ready slitter designed to keep widths consistent, edges clean, and roll hardness controllable across different operators and shifts.

On the floor, the difference feels immediate. The machine runs with a steady mechanical hum, and the PLC + touch screen workflow replaces guesswork with repeatable settings. Operators can move from one job to the next without re-learning the machine, and supervisors can standardize parameters for key SKUs. For B2B buyers, this is not about “features.” It’s about fewer claims, fewer rejected rolls, less downtime, and a cleaner handoff from slitting to packing.

Product Features and Highlights

A slitting machine earns its place by reducing the invisible costs of converting: setup drift, scrap at the start of each job, and inconsistent roll tightness that shows up only after shipping. This machine is designed to make those problems easier to control, without forcing a complicated footprint or a high maintenance burden.

PLC + touch screen control for clearer setup, repeat orders, and reduced operator dependence

0–200 m/min speed range to match different paper grades and quality targets

0.1 mm precision to support tight-width requirements and reduce trim waste

650 mm max unwind OD to handle common jumbo roll logistics efficiently

Dual rewinding capacity (260 mm / 500 mm) to support different finished roll diameters and packing formats

Two practical model choices (350 mm or 450 mm) so you don’t pay for unused width

Voltage customization to reduce installation friction across regions

Suitable Materials and Industries

This machine is used for slitting and rewinding across a wide range of roll materials, which is especially important for converters serving multiple customer segments. Typical materials include paper and also roll goods used in packaging and industrial supply chains such as films and foils, non-woven fabric, PVC, PET, and technical sheet materials used for shielding, insulation, conductivity, and adhesive-based products. That flexibility matters because B2B orders rarely stay the same for long: one month you may be converting packaging paper, the next month you may be supporting a customer with specialty roll stock.

Industries commonly served include printing, packaging, medical supplies, electronics and 3C, rubber and automotive, and general converting. If you’re running contract converting, this range lets you keep a single platform while adapting cutting widths, winding diameters, and process settings to new SKUs. The result is a calmer production schedule and fewer “one-off” purchases that complicate maintenance and training.

Slitting and Rewinding Performance

Speed and accuracy only matter if they translate into usable output. With a slitting speed range of 0–200 m/min, you can tune the line to your paper grade, target roll hardness, and edge quality expectations. When paper is softer or dustier, you can slow down for cleaner edges and better roll formation; when you’re processing stable stock, you can increase throughput without turning the slitter into a bottleneck.

The 0.1 mm slitting precision supports tighter width tolerances and helps reduce cumulative waste. In real production terms, higher repeatability means fewer “trial cuts,” fewer partial rolls, and less trimming to rescue imperfect output. Combined with stable rewinding, this helps your finished rolls look and feel consistent: neat edges, even layers, and a roll surface that stays smooth rather than stepping or telescoping during handling.

Unwind and Rewind Handling

Roll handling is where many converting lines silently lose time. The machine supports a maximum unwinding diameter of 650 mm, which fits common jumbo roll supply patterns and reduces the frequency of roll changes. Fewer changes mean fewer stops, less chance of misalignment during threading, and a steadier rhythm for operators.

For finished rolls, the machine provides two rewinding diameter capacities: 260 mm (upper) and 500 mm (lower). This gives you flexibility for different packing and logistics requirements, such as smaller rolls for retail-style cartons or larger rolls for industrial consumption. In practice, rewind capacity affects not just output size but also shipping stability. A properly formed roll with consistent tightness arrives looking “factory-fresh,” not soft at the edges or uneven across the face. If your customers run their own downstream machines, this consistency reduces their line stops too, which is a strong selling point in B2B supply relationships.

Control System and Operator Experience

In converting shops, consistency is often limited by how information is transferred between people: one operator “knows the feel,” another operator guesses. PLC + touch screen control helps make your process teachable and repeatable. Settings are visible, jobs are easier to standardize, and supervisors can build internal guidelines that reduce variation across shifts.

From an operator’s perspective, the value is simple: fewer manual adjustments, fewer measurement mistakes, and less time spent correcting after a cut is already made. The interface supports clearer job execution, especially when you are switching widths frequently or running small-lot orders. For the plant manager, this means training becomes faster and output becomes less dependent on a single experienced worker. Over time, that improves scalability and makes quality audits easier to pass.

Quality, Waste Control, and Edge Cleanliness

Quality in slitting is not only a measurement issue; it’s a visual and tactile promise. Buyers can see if edges are clean and feel if the roll is tight and uniform. By focusing on precision and stable winding, the machine helps reduce common quality failures such as uneven edges, roll telescoping, and inconsistent roll hardness that causes deformation in storage.

Waste control improves when jobs are repeatable. If your widths hit target quickly, you create fewer “setup scraps,” and the trimmed edges become more predictable for collection and disposal. This has a direct cost impact in high-volume operations where paper waste and downtime compound quickly. A practical way to maximize results is to match speed to material behavior, then lock those best-performing settings into your internal SOPs so every operator can run the same standard.

Model Selection Guide

Choosing the right model is usually a business decision disguised as a technical decision. If your product mix includes many narrow widths and you’re optimizing for footprint, LT-350 is often the efficient choice because it covers the 0–350 mm slitting width range with strong throughput and lower power demand. If you need additional width flexibility for broader formats or you want more room for future SKUs, LT-450 provides 0–450 mm capacity while maintaining the same speed and precision targets.

Below is a quick selection chart to align the model with your converting plan. If your purchasing team is comparing suppliers, this helps convert “spec talk” into production planning: what widths you run, what diameters your customers request, and how you want to balance cost with flexibility.

| Model | Slitting width | Speed | Precision | Max unwind OD | Max rewind OD | Total power | Typical fit |

| LT-350 | 0–350 mm | 0–200 m/min | 0.1 mm | 650 mm | 260/500 mm | 3 kW | Narrow formats, space-sensitive plants |

| LT-450 | 0–450 mm | 0–200 m/min | 0.1 mm | 650 mm | 260/500 mm | 3.7 kW | Wider formats, SKU expansion planning |

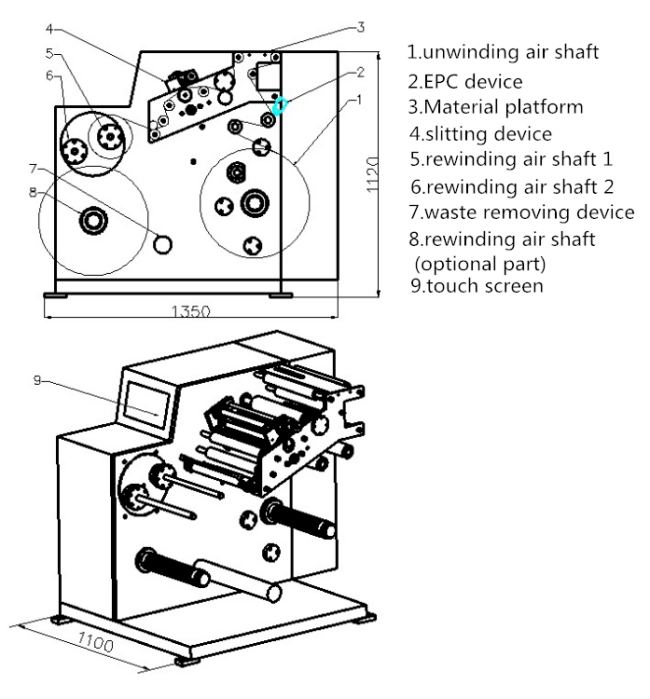

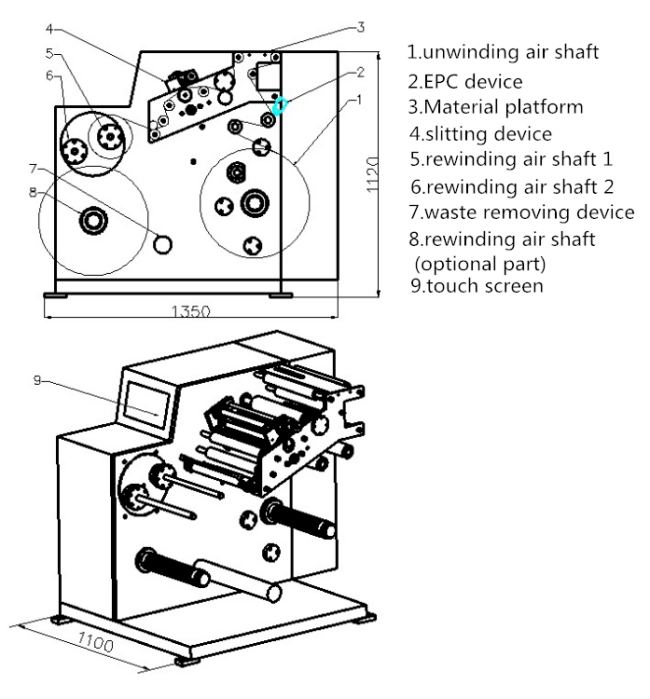

Machine drawing

Machine photo

Machine technical parameter

| Item Number | LT-350 | LT-450 |

| Slitting Width | 0-350mm | 0-450mm |

| Slitting speed | 0-200 m/min | 0-200 m/min |

| Slitting precision | 0.1mm | 0.1mm |

| Maximum unwinding diameter | 650mm | 650mm |

| Maximum up/down rewinding diameter | 260mm/500mm | 260mm/500mm |

| Package dimension | 1100*1300*1100mm | 1100*1400*1100mm |

| Weight | 680kg | 750kg |

| Total Power | 3kw | 3.7kw |

| Voltage | Customized | Customized |

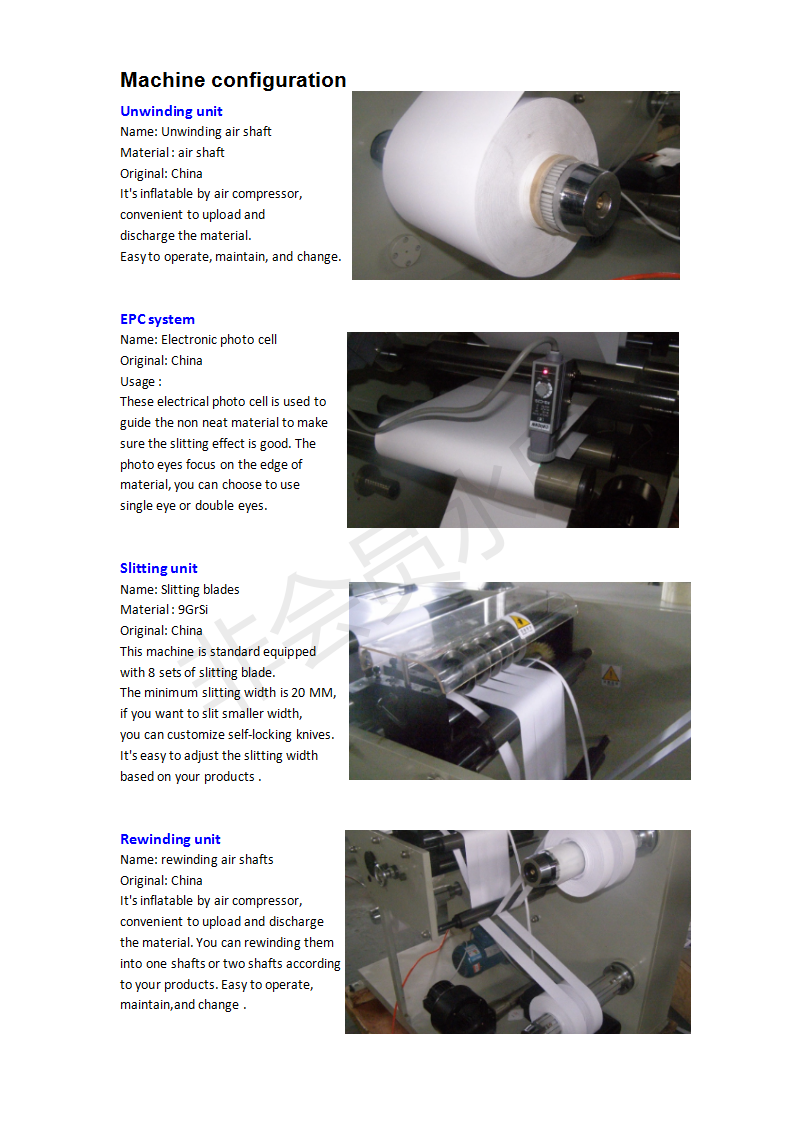

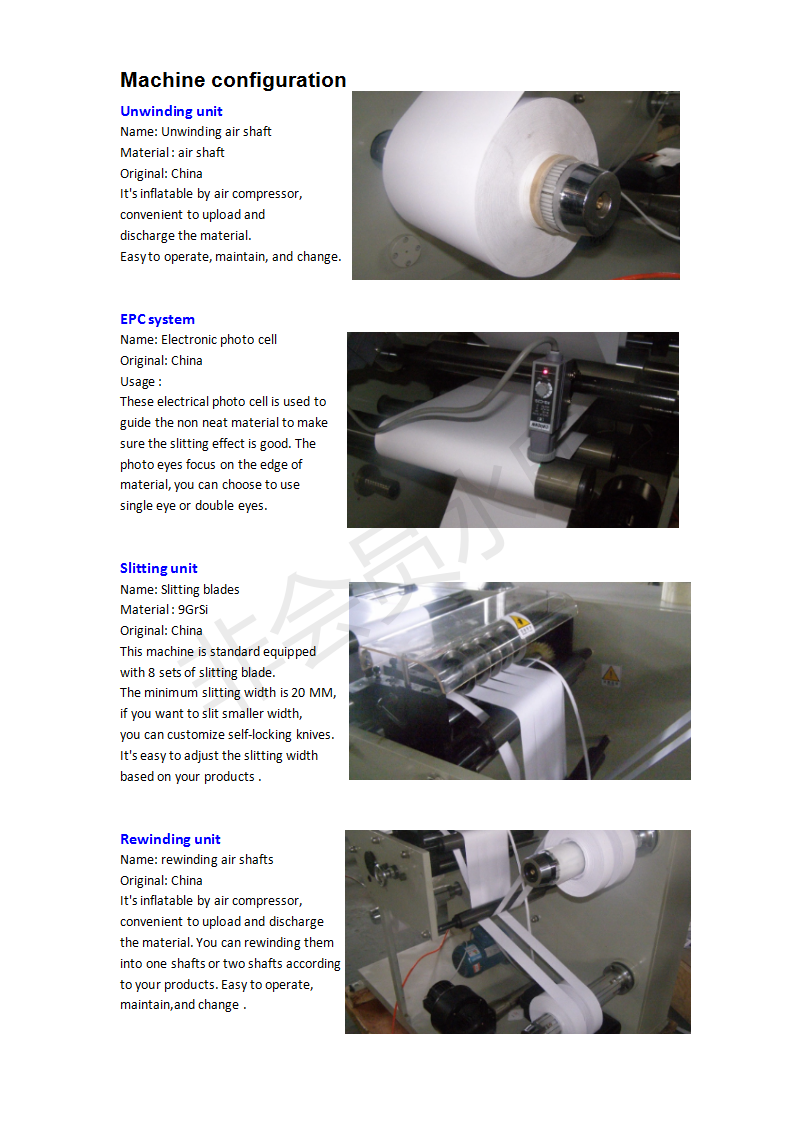

Machine configuration

Why Choose Us

We focus on practical converting machinery designed for real shop conditions: mixed order sizes, changing materials, and constant pressure on delivery timelines. Our manufacturing experience supports a disciplined approach to quality control from incoming materials through assembly and final inspection, and our machines are built with export delivery in mind so your installation schedule is protected, not delayed by avoidable issues.

Beyond the machine itself, we support B2B buyers with customization readiness. Voltage can be configured to your region, and our engineering team can work from your roll samples and production targets to confirm suitability. If your application requires special handling for sensitive materials, adhesive layers, or unusual roll formats, we can align the configuration and commissioning plan to your process so you get stable output quickly.

FAQ

1. Are you a manufacturer or a trading company

We are a professional manufacturer with over 10 years of experience in converting equipment.

2. What materials can this machine handle

It is widely used for slitting and rewinding on paper and many roll materials, including films, metal foils, non-woven fabric, PVC, PET, and technical materials used for shielding, insulating, conductive, and adhesive applications.

3. How do I choose between LT-350 and LT-450

Choose based on your maximum finished roll width and your future SKU plan. If you mostly slit within 350 mm, LT-350 is efficient. If you need up to 450 mm or want extra flexibility, LT-450 is the safer long-term choice.

4. What information do you need for an accurate quotation

Your material type, jumbo roll OD, core ID (if applicable), target slit widths, finished roll OD targets, production speed expectation, and your local voltage standard.

5. Can the voltage be matched to our country

Yes. Voltage is customized.

6. Where is the factory located

The factory is located in Yancheng City, Jiangsu Province, China.