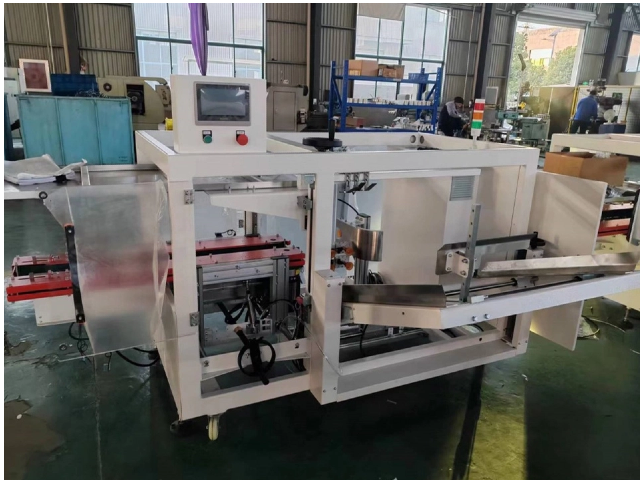

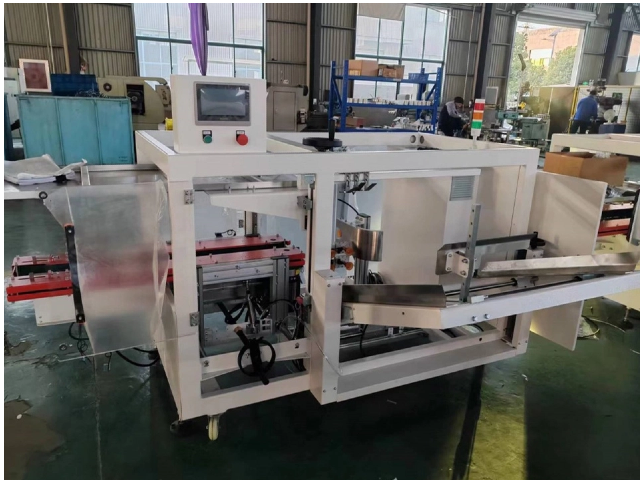

The manufacturing world is undergoing a technological revolution—and packaging automation is no exception. As production facilities shift toward smart, connected, and scalable operations, the role of the case erector is transforming dramatically. Once limited to simply forming boxes, today’s case erectors are evolving into intelligent systems powered by robotics, artificial intelligence, and real-time analytics. At Yancheng Longterm Machinery Co., Ltd, we’re at the forefront of this transformation, building next-generation case erector systems that are not only faster and more efficient but also smarter and more adaptable than ever before.

Automation and Robotics Integration

The future of packaging is automated—and robotics is leading the charge. Modern case erector machines are now incorporating robotic arms and AI-powered systems that perform tasks with levels of precision and consistency far beyond traditional methods. Whether it's picking and placing box blanks, folding flaps, or sealing cartons, robotic integration enables smoother, faster, and more flexible performance.

Advanced machine vision systems can now scan every box in real time, detecting imperfections or misalignments instantly. AI-driven error detection reduces the need for human supervision and significantly minimizes downtime caused by material inconsistencies or jamming. At Longterm Machinery, we are continuously upgrading our machines with smarter robotic components to ensure they adapt to increasingly complex packaging environments.

In high-volume operations, these features translate into thousands of error-free cartons erected per hour—with minimal operator input. As labor shortages continue to impact industrial workflows globally, this level of automation is becoming not just a luxury but a necessity.

IoT and Real-Time Monitoring for Predictive Maintenance

In the era of Industry 4.0, data is power. Integrating Internet of Things (IoT) technologies into case erector systems enables real-time visibility into machine performance, health, and productivity.

Smart sensors embedded throughout the machine constantly collect and analyze data, from motor temperature and vibration to carton throughput and air pressure. This information feeds into cloud-based dashboards, allowing managers and technicians to monitor performance remotely. More importantly, predictive maintenance algorithms can identify subtle changes that precede mechanical issues—prompting service before a breakdown occurs.

At Longterm Machinery, we offer IoT-enabled case erectors that deliver detailed uptime analytics, alert notifications, and usage reports. These tools help customers extend machine lifespan, reduce unplanned downtime, and lower total cost of ownership.

As factories grow more connected, the ability to access and act on real-time performance data will separate reactive facilities from proactive leaders. Investing in smart, data-driven equipment is no longer optional—it’s the new baseline for operational excellence.

Enhanced Flexibility for Multi-Format Packaging Lines

In the age of mass customization, packaging lines must handle more variety than ever before. The days of long runs using a single box size are over. E-commerce, subscription services, and mixed SKU logistics demand flexibility—and modern case erectors are rising to meet that demand.

Future-ready case erector systems are being built with modular designs that support multiple box formats without extensive manual changeovers. Operators can switch between different sizes, flap styles, or sealing methods with a few taps on a touchscreen. Machines equipped with dual magazines can alternate between box blanks, feeding the right size on-demand.

At Longterm Machinery, our latest models are designed to serve dynamic production needs. With rapid changeover capability, automated size detection, and pre-programmed format settings, our case erectors keep pace with shifting packaging requirements—without sacrificing speed or accuracy.

This flexibility is especially valuable in fulfillment centers, where every order may require a different package size. By reducing the time and labor involved in reconfiguring machinery, businesses can achieve more uptime, lower waste, and faster delivery times.

Sustainability Built Into Smart Systems

Smart doesn’t just mean fast—it also means responsible. Sustainability is a driving force behind packaging innovation, and the modern case erector is playing a key role in this movement.

First, smart case erectors help reduce material waste. By forming boxes more precisely and adjusting automatically for board inconsistencies, they ensure minimal errors and fewer rejected cartons. Some machines can even interface with box optimization software to ensure the most material-efficient configurations.

Second, energy-efficient components such as servo motors, low-resistance drives, and programmable standby modes drastically reduce electricity consumption. At Longterm Machinery, we incorporate these features into our new-generation systems, allowing customers to meet both performance and sustainability benchmarks.

Third, smart machines support the use of recycled and biodegradable materials. With adaptive forming mechanisms and adjustable pressure settings, our case erectors can reliably process corrugated boards made from alternative fiber sources or high post-consumer content.

As companies set ambitious carbon neutrality targets, sustainable automation will be critical. Smart case erecting systems allow manufacturers to meet regulatory requirements, reduce carbon footprints, and maintain operational efficiency—all at once.

What’s Ahead: Predicting the 2030-Era Case Erector

So what’s next for the case erector? Looking ahead to 2030, we envision a future where box erecting becomes not just automated, but fully autonomous.

Machine learning algorithms will enable systems to self-optimize in real time, adjusting forming speed, sealing methods, and maintenance intervals based on live data. Future machines may even use augmented reality for guided troubleshooting and remote collaboration.

Collaborative robots (cobots) could work alongside human operators, learning from their actions and gradually taking over repetitive tasks. Entire packaging lines—integrating erectors, packers, labelers, and palletizers—could communicate with one another, dynamically adjusting workflows to match order volume or product variation.

At Longterm Machinery, we’re investing heavily in R&D to push the boundaries of what's possible in case erecting automation. Our vision includes self-configuring erector modules that can be added or removed like building blocks, allowing businesses to scale rapidly without a full equipment overhaul.

This evolution won’t just change packaging machinery—it will redefine packaging strategy. Businesses that adopt these technologies early will lead the charge in smart manufacturing.

Conclusion

The case erector of the future is no longer just a box maker—it’s a smart, scalable, and data-driven system that empowers manufacturers to achieve more with less. From AI-powered robotics and IoT-based diagnostics to multi-format flexibility and sustainability integration, this technology is at the heart of the next wave in packaging automation.

At Yancheng Longterm Machinery Co., Ltd, we’re proud to be leading this transformation. Our intelligent case erector solutions are designed not only to meet today’s operational challenges but also to prepare your business for the opportunities of tomorrow.

Contact us today to learn more about how our next-generation case erector machines can future-proof your packaging line and take your production strategy to the next level.