Product Description

In many plants, the “hidden bottleneck” isn’t the press, the laminator, or the packer—it’s the moment a heavy roll becomes a stack of sheets. When that conversion is slow or inconsistent, everything downstream feels it: operators chase length drift, scrap rises at the edges, and the line loses its rhythm.

This Roll To Sheet Cutting Machine is built for that exact handoff. You load the roll, set the length, and the machine takes over—feeding, cutting, and outputting sheets that feel uniform in the hand and look consistent on the pallet. The cut edge is crisp, the sheet length stays steady, and the motion has that controlled servo “hum” that signals stability rather than strain. For B2B buyers, the value is straightforward: fewer interruptions, less material loss, and a more predictable daily output that planning teams can trust.

Instead of treating roll-to-sheet as a rough pre-step, this machine treats it like a precision process—so your operation can move faster without becoming fragile.

Product Features and Highlights

High precision cutting

Speed that supports production

Wide web-width flexibility

Broad thickness capability

Control system built for repeatability

Application-driven options

Eye mark device optional (useful when registration marks are required)

Kiss-cut optional for processes that require partial cutting

Air shaft as the loading shaft for practical roll mounting and changeovers

Optional accessories: static eliminator and conveyor belt

Automatic unwinding function to reduce manual handling during runs

Materials and Typical Applications

This machine is designed for manufacturers who run multiple roll substrates and want one conversion platform that can keep up without constant “baby-sitting.”

Flexible packaging and converting

Plastic films such as PET, PC, PVC

Metal foils like aluminum foil and copper foil

Paper and paperboard workflows

Electronics and technical materials

Battery and energy materials

Specialty textile-like rolls

If your production line depends on stacks that stay square, sheet length that stays true, and fewer “mystery” defects caused by unstable feeding, roll-to-sheet precision becomes a measurable competitive advantage.

Why Choose An Automatic Roll to Sheet Cutting Machine?

1. High efficiency: The roll to sheet cutting machine can cut paper quickly and accurately, improving production efficiency.

2. High precision: The roll to sheet cutting machine has a high-precision cutting function, which can achieve precise cutting of paper of various specifications.

3. High degree of automation: The roll to sheet cutting machine can automatically complete the process of cutting, feeding, and collecting without manual intervention, which greatly improves the work efficiency and safety.

4. Wide applicability: The roll to sheet cutting machine is suitable for various types of paper, including soft, hard, double-sided coating, etc.

5. Resource saving: The cutting accuracy of roll to sheet cutting machine is high, which can effectively avoid the waste of paper due to inaccurate cutting, thereby saving resources.

6. Good environmental protection: The roll to sheet cutting machine adopts advanced technology and equipment, which can achieve low energy consumption and low pollution production mode, and meet the requirements of environmental protection.

Features Of roll to sheet cutting machine

1. The max cutting width option: 360, 500, 600, 700, 1000mm.

2. Cutting Precision: 0.03mm

3. Material thickness: 0.5mm-20mm (according to different materials)

4. Cutting speed: 100cut/min;

5. Both kiss-cut and complete cut are available; Complete cut is for standard machine, and kiss-cut is an option;

6. A conbination of PLC and servo motor.

7. Eye mark device for optional

8. An air shaft as the loading shaft;

9. Two accessories, static eliminator and conveyor belt, for you to choose

10. Automatic unwinding function;

Machine Parameters

| Item Number | LT-360 | LT-500 | LT-600 | LT-700 | LT-1000 |

| Web Width | 0-360mm | 0-500mm | 0-600mm | 0-700mm | 0-1000mm |

| Cutting length | 0-9999.99mm | 0-9999.99mm | 0-9999.99mm | 0-9999.99mm | 0-9999.99mm |

| Cutting speed | 100 cut/min | 100 cut/min | 100 cut/min | 100 cut/min | 100 cut/min |

| Cutting precision | 0.03mm | 0.03mm | 0.03mm | 0.03mm | 0.03mm |

| Voltage | 220V/380V | 220V/380V | 220V/380V | 220V/380V | 220V/380V |

| Size | 1100x1420x1280mm | 1250x1420x1280mm | 1350x1420x1280mm | 1450x1420x1280mm | 1730*1420x1280mm |

| Weight | 320kg | 380kg | 400kg | 420kg | 450kg |

| Total Power | 2.2kw | 2.2kw | 2.2kw | 2.2kw | 2.2kw |

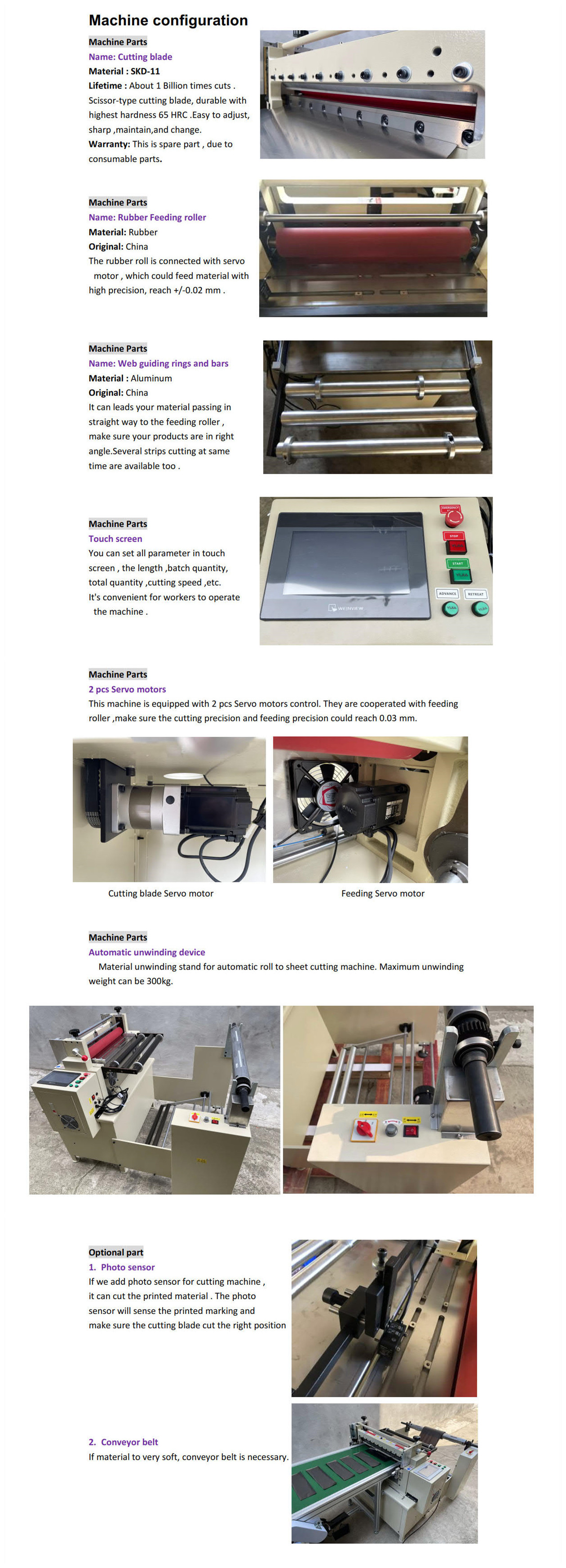

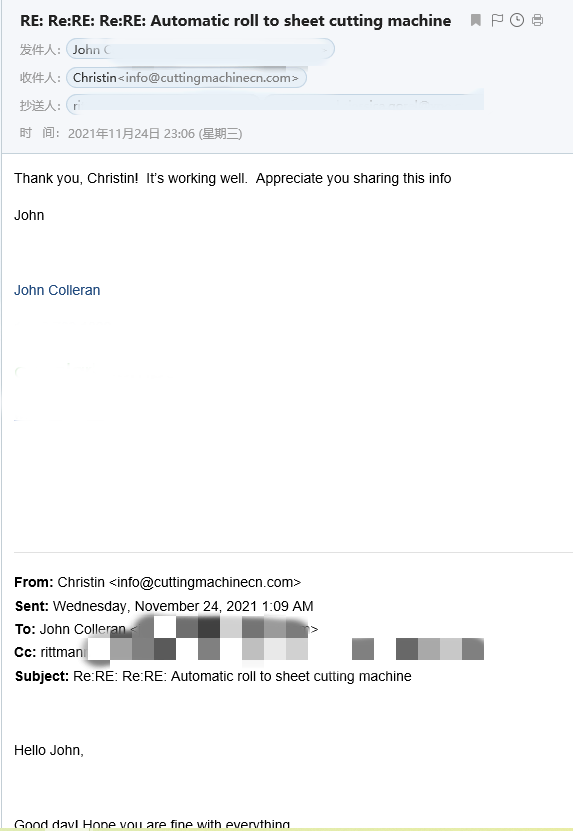

Machine configuration

CE certificate

Comments from customers for roll to sheet cutting machine